Beskrivelse

INFO: Prisen inkluderer universale festelister (passer våre v5 og v6 rammer uten lim, ellers anbefaler vi bruk av Casco Xtremfix lim som vi også fører for å feste listene til trerammer / eksisterende alurammer, se videoer lenger ned i produktteksten). Det medfølger også vårt spesialutviklede proffverktøy "UltraTucker PRO" som gjør installasjonen enkel. Vi anbefaler at en går gjennom listene med dette verktøyet en gang før montering da listene er veldig stramme fra fabrikk. Du drar da bare gjennom listen med tuppen / enden av verktøyet og "sliper av" litt av plasten for å åpne sporet og dermed gjøre det enklere å montere inn duken. Husk å stramme godt til!

Selv om prisen på v7 uansett er relativt sett høy (som følge av en svært komplisert og krevende produksjonsprosess), er det viktig å understreke at gainnivåer på 0,93 fra en akustisk lerretsduk som samtidig har bildekvalitet på høyde med det aller beste av ikke-transparente PVC-lerreter er helt unikt. Mer lys gir rom for enten bedre HDR, eller muligheten for å strupe irisen og dermed få bedre sortnivå.

AVshop drifter som mange sikkert vet også DreamScreen, der vi stadig øker både i omfang og renomé både her til lands, men også i det store utland, spesielt da i USA, (faktisk) Kina samt EU.

UltraWeave v7 er vår 7. generasjon, der fokus er lagt på å øke lysstyrken / gain til det maksimalt oppnåelige mens vi samtidig ivaretar "unity gain", dvs. total matt, bilderefleksjon og høy lydtransparens.

v7 benytter seg av 4 lag stoff av ulike densiteter og type, mens v6 benytter 3 lag. Gain har vi dermed klart å øke fra 0.80 på v6 til 0.93 på v7, eller 16% mer. Dette er da helt i toppklassen og kan sammenlignes direkte med en perforert vinylduk med tanke på lysstyrke, men uten store sjenerende hull og ikke minst langt bedre akustisk transparens. Vi får til dette som følge av vår patenterte multilags oppbygning.

Akustisk sett er fremdeles v6 referansen (1,5dB drop på v6 mot 3,3dB drop på v7, der begge er svært gode tall, men v6 forblir referansen i så måte), og med unntak av mer lys på v7 er v6 like skarp på videosiden, så for folk med lerreter opp til type 2,6-2,8m bredde (og en vanlig hjemmekinoprojektor) er på ingen måte v6 utdatert. v6 vil dermed selges samtidig som v7 og er ikke et utgått produkt.

Vi har v7 installert i vårt største demorom på en ramme med 3,9m bredde, der en JVC N7 og en Panamorph DCI linse står for projiseringen. På kildesiden har vi en fersk topptunet madVR-basert HTPC. Greit å nevne at det også står et fullt 16-kanals Alcons-basert lydsystem i nevnte rom.

VELKOMMEN PÅ DEMO!

Informasjon fra produsenten

NOW PATENTED! The unique technique used to produce the UltraWeave v5, v6 and v7 has now been approved by both the US Patent and Trademark office as well as the European Patent Office, EPO. This allows us to pour even more resources into this great line of products, while you can rest assured that the product you are considering is truly unique and the result of 15+ years of extensive research and development.

MAIN SPECIFICATIONS

| Gain (D65 benchmarked) | 0.93 |

| Acoustical Transparency | 3,3dB average loss |

| Viewing cone | 160° |

| Reflection | 100% matte unity gain principle |

| Supported resolutions | >8K. Zero moiré at any resolution |

| Buildup | 4 layered bonded weave + knit (patented) |

| Black backing | Integrated |

| Fire retardant | Yes, US NFPA 701 certification |

| Available sizes | 2,3x4m and 2,3x5,3m rolls |

| Available accessories | Universal fabric grip railsFabric installation tool

Regular and motorised masking frames |

INNOVATION BY THE POWER OF 4

For the development of our 7th generation UltraWeave we had a clear mission;

Utilise our patented multiple layered principle in order to increase gain levels to the absolute possible maximum while still retaining the ultra matte characteristics of that of a perfectly performing unity gain type of screen. At the same time our goal was to keep the acoustical transparency at the highest possible level achieving this.

Our solution to this challenge was adding yet another custom designed reflective layer, increasing the amount of layers from 3 to 4. One front ultra-fine woven and three layers of knitted fabrics in different layouts and configurations. Everything is custom made down to the thread diameter and carefully tuned appearance of each layer.

While each layer has a mission of its own, it is through the interaction with the other layers its inherit potential is revealed - true innovation by The Power of 4!

UNPRECEDENTED UNITY GAIN LEVELS

The v7 increases gain from our 6th generation fabrics by 16%, with an official D65 benchmarked gain value of 0.93 from 0.80 on our v6 fabrics.

A solid, non acoustical transparent screen based on a unity gain principle will never surpass a gain value of 1.0, meaning the v7 deducts <10% of the light while still remaining highly acoustically transparent. This is comparable to the gain level one might expect from a micro perforated 1.0 unity gain vinyl screen, but without the drawbacks such as highly visible perforations and far lower acoustical transparency. It is also comparable to the highest gain woven screens, but without the use of a coarse, potentially visible woven structure that might also cause moiré.

One important note on gain levels is that, unfortunately, many manufacturers tend to inflate their official figures far beyond reasonable levels. We have therefore taken professional measurements, performed by a THX / ISF professional, benchmarked using the one screen fabric we are confident provides accurate figures; the industry standard Stewart Studiotek 100 (our favourite non-acoustical transparent screen material by the way).

We have compared the gain of the Studiotek 100 to a woven screen stated to be 1.1 gain by the manufacturer. Our measurements indicate an actual gain of 0.86, i.e. inflated by more than 20%.

All measurement raw data is located at the bottom of this page.

A unity gain type of screen like the UltraWeave v7 reflects incoming light in all directions, creating perfect image uniformity. This ensures that the image appears perfectly lit throughout the screen area for the entire audience, becoming increasingly important nowadays as screens size increases in relation to seating distance due to 4K resolutions and above becoming the norm, plus of course, an ultra-fine screen fabric such as the v7 allows for the increased impact of a more immersive video experience.

Example of how a glossy screen coating might produce a sheen (and potentially also speckle), compared directly to the v7. There are actually a number of 1.0 gain (or lower) screens that has this shimmer applied to its coating as well, whereas this particular fabric is a regular 1.0 gain PVC non-AT variant. For positive gain or filtered screens, this effect might be far more visible than this example. This issue is typically visible on brighter images, and particularly noticeable on moving camera shots (pans / tilts). What you see instead of the projected image is the actual screen structure appearing overexposed, highly reducing the quality and also peak luminance details when visible, caused by the burned out peaks. The v7 is, however, completely matte and follows the unity gain principle, never allowing for these types of artefacts reducing the performance of the projected image.

ULTRA-FINE SURFACE DENSITY

The v7 allows for seating as close as 1m / 3ft distance without any visible structure from either perforated holes or coarse weaves distracting you from enjoying the displayed content.

A coarser woven screen will also run the risk of producing moiré, especially once resolutions increase to 4K, 8K and beyond moving forward. Moiré might also occur as a consequence of changing the projection technology, such as moving from D-ILA to a lower pixel density DLP or LCD (even at the same resolution). As people tend to keep their screens longer than they do their projectors, investing in a v7 screen fabric would ensure that moiré will never occur - at any resolutions - ever. This is due to the extremely tight, randomised front woven surface layer of the v7, emulating the coating of a non acoustical transparent regular screen.

This is an example of moiré, a phenomena occurring if pixels from the projector interlock with the pattern of the weave. This will never occur with the UltraWeave.

The below comparison includes the v7 at the top, a micro-perforated PVC fabric to the left and the tightest single-layered woven screen fabric we have found to date (this is the material also used for the comparative gain benchmarking).

ULTIMATE SHARPNESS

This is an actual side-by-side comparison of a non-AT PVC-based projection screen. The unique patented buildup of the v6 and the v7 UltraWeave emulates the randomised surface coating and consequently the sharpness of a regular (non-transparent) screen.

The above image compares the v6 to a random custom designed single reflective layered knitted fabric, which is what we used for our 3. generation fabrics back in 2009 as well. However, in order to increase sharpness, from our 5. generation onwards, we added the now patented ultra fine front randomly woven layer, and rather used the knitted fabrics as the second (and third for the v7) reflective as well as a black backing layer, combining the sharpness and density of the weave AND the acoustical transparency of the knit. Although knitted fabrics are quite good in both structural density and acoustical transparency, the fact remains that light blooming / spill via the knitted "fluffy" cavities reduce sharpness quite significantly. Edges appear more blurred and details simply "wash out". Maximum reflected sharpness will become increasingly important moving forward as 4K, 8K and even higher resolutions become available. In other words, the patented design of the v6 and v7 offers The Best of Two Worlds - and consequently maximum sharpness and reference acoustical transparency.

This picture of the v6 is taken by one of our valued customers in Germany, w.mayer, depicting the extremely sharp reflection from his Barco Thor 15.000 lumen 6P 3-chip DLP laser (please click the image for a larger, 4K, preview). Quote from w.mayer;

"When you have a fabric screen that not show the pixels this material soften the picture to some degree for sure. This v6 material was the first that not do it! It act like a conventional screen so it not decrease at all details and sharpness and not soften the picture. This is “to my knowledge” the first fabric that act this way! WOW!"

Read more here: http://dci-forum.com/d-cinema-hi-end-cinema-home/11/barco-thor-4k-6p-residential-laser-projector-best-world/1710/msg5259;topicseen#msg5259.

INTEGRATED BLACK BACKING

The unique buildup of the UltraWeave includes an integrated black (custom knit highly AT design) backing.

The bonded nature secures that no blooming effect becomes apparent, as even the slightest distance between the layers, a common issue when manually attaching black backing to regular woven or knitted fabrics, will reduce both contrast and overall sharpness especially apparent on bright objects in dark surroundings by introducing light bleeding.

In addition, which is very important for the DIYers as well as the baffle wall installations, stray light is effectively taken care of, so that objects in the back of the screen, such as wooden studs, speakers etc., will not be visible through the fabric.

Example of how blooming appears on typical highly lit objects towards a dark background. Even the slightest distance between the reflective layer and the black backing might introduce this issue. The UltraWeave is perfectly factory bonded and will never produce this artefact on its own merit.

ACOUSTICAL TRANSPARENCY LEVELS

The UltraWeave v5-v7 achieves its reference acoustical transparency levels by combining a patented layout of woven and knitted layers. The woven ultra-fine front layer provides structural sharpness, and is highly audiotransparent due to the virtue of being extremely thin, while the remaining reflective knitted layers adds brightness while also allowing air (sound) to pass very efficiently.

Although we have modified and perfected each layer to accommodate the highest possible audio transparency on the v7, adding another reflective layer does impact the acoustical blockage levels to some degree. The UltraWeave v6 will remain our reference in terms of acoustical transparency, averaging at a record low 1,5dB blockage. The v7 is still what we consider highly audiotransparent, averaging at 3,3dB. From our perspective, the v7 balances the audio and video aspect quite elegantly.

Compared to other higher gain woven screens or certainly perforated PVC screens this level is still highly competitive, especially when taken into consideration it includes our integrated black backing.

The woven screen fabric used in our gain benchmark comparison measured more than 5dB peak drop without black backing that normally adds another 1-2dB. 6-7dB drop is quite hard to compensate for even using extensive amounts of equalisation.

Other higher gain woven screens might block less of the audio than the example we ran these comparisons to, but in all the cases we have observed, higher gain is then obtained by adding a more reflective coating to the threads (as opposed to simply tightening the weave like is the case for the fabric we have tested in our comparison, which remains quite matte) used in weaving the fabric causing shimmering and in reality a non-matte / non-unity gain image basis.

A perforated PVC screen has even greater audio blockage, ranging from 7 - >10dB.

The v6 and the v7 will be sold parallell, whereas your personal priorities, screen size, projection system and overall audio setup would be the basis of what makes out your dream screen. Please do not hesitate contacting us for advice!

AVAILABLE SIZES

Our initial production run is made with a fabric height of 2,3m / 90 1/2" and a length of either 4m / 157 1/2" or 5,3m / 208 1/2". The 4m length accommodates a 16:9 screen size up to 171" diagonal (3,8m / 149 1/2" image width), while the 5,3m length accommodates a 2.40:1 screen size up to 217" diagonal (5,1m / 200 3/4" image width).

PACKAGING

We have placed a lot of emphasis on packaging to make certain your new screen fabric arrives in perfect condition.

In addition to packaging the fabric alongside an additional protective layer of fabric (which also comes in handy in terms of protecting the screen during installation), we are now floating the fabric inside a double set of tubes.

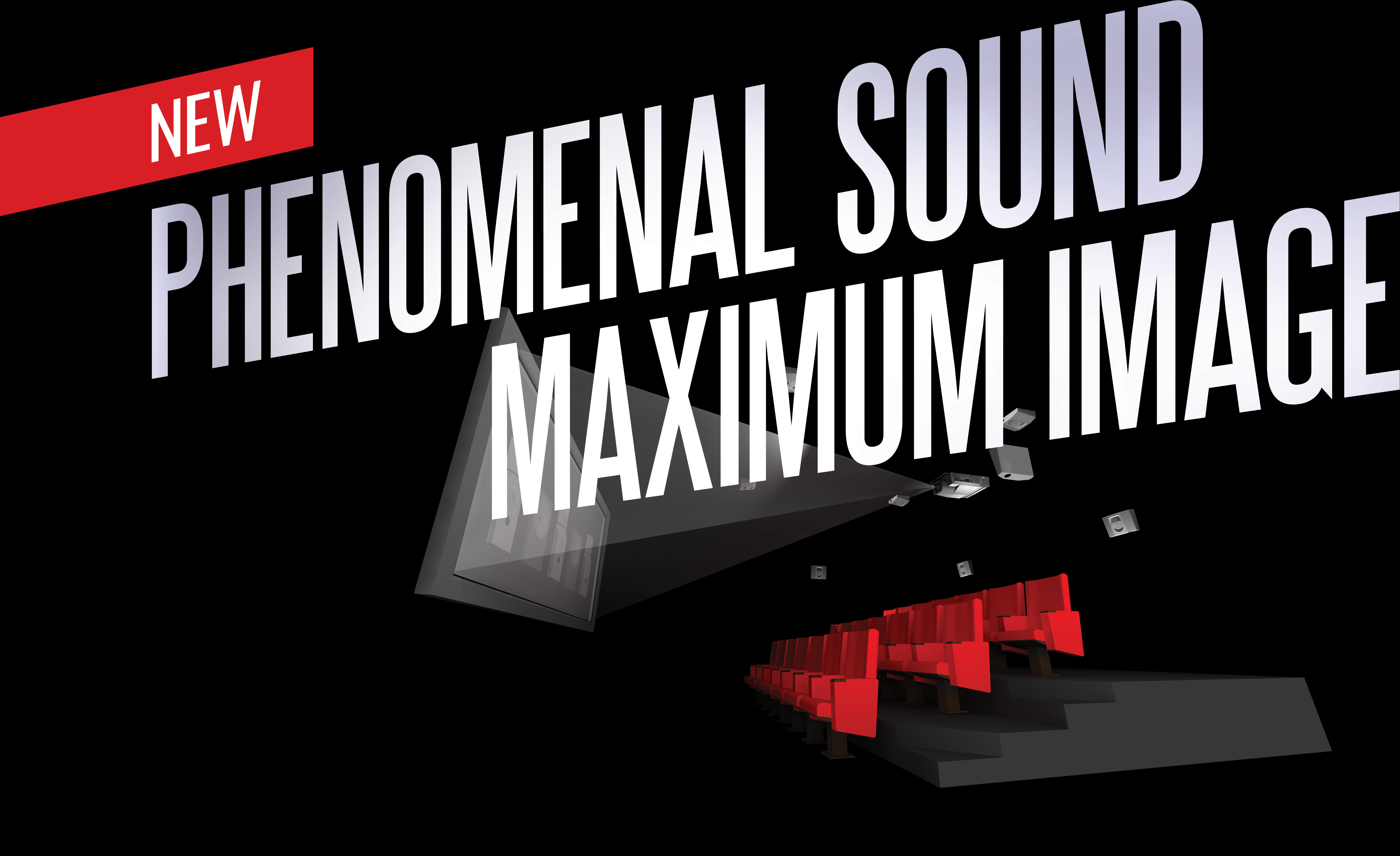

TEXTILESHIELD - FOR THE ULTIMATE PROTECTION

TextileShield PRO

In our search to make out the perfect projection screen fabric, we are fully aware that no matter how we are able to excel in image- and sound quality, practical usage and worry free ownership is also an essential part of making use of a reference quality acoustical transparent cinema screen. While the regular v6 and v7 also allows you to clean off light stains such as small insects using a slightly damp fiber cloth or simply scratching the stain off, the TextileShield protected v6 and v7 shields off for just about anything, including substantial spills of wine, coffee, and even allows for far easier release and removal of what is normally considered "impossible stains" from oil / fat or all kinds of solid types of dirt.

The TextileShielded UltraWeave v6 features the full performance of the v6 and v7 in terms of gain, D65 tracking, overall image quality and also its reference acoustical transparency.

The protection system works at a sub fiber "nano" level and is applied as part of our custom production cycle prior to bonding the layers to ensure maximum performance. The TextileShield PRO protection is applied to both front layers (the UltraWeave uses a patented, hybrid multiple layered system), ensuring superior strength, allowing us to include a 10 year limited stain warranty. If any stain settles for some reason and you are unable to get the stain off, we will ship you a new fabric for free, simple as that. The warranty is limited to two replacements per purchase and you would need to send us a picture of the damaged fabric being cut diagonally after the receipt and installation of the replacement. Does not cover damages caused by fire, flooding or any other damage caused by external factors other than from the intended use (i.e. a projection screen).

Please refer to the following page for further information of the features and limitations of the UltraWeave v6 and v7 TextileShield PRO and TextileShield >>.

INSTALLATION VIDEOS

Quick guide to show you how to very easily install the UltraWeave onto one of our frames. We actually developed our own tucking tool recently, the UltraTucker PRO, making it easier and faster than ever to install your new UltraWeave.

This quick guide shows you how to make a DIY wooden framed screen using the available grip rails

This video displays how to recycle your existing aluframe using the grip rails available. Please note that all DreamScreen frames does not require the use of glue to attach the grip rails as they have a pre-fitted tracks integrated.

INSTALLATION INSTRUCTIONS >>

PS! Universal grip rails that fit out frames (without the use of glue), DIY wooden frames as well as retrofitted aluminum frames are also available.

Also, we now include our new in-house designed tucking tool, the UltraTucker Pro; an ergonomic, durable and highly efficient installation tool for the UltraWeave onto the grip rails!

BACKGROUND

The DreamScreen UltraWeave v7 is our 7. generation acoustic transparent (AT) fabric. Throughout the last 15 years we have tested, prototyped, produced and sold a number of technical solutions.

In our opinion, the best possible screen is the one that does not even make its appearance; you simply see what is projected upon it, nothing less, nothing more.

By combining a high-gain (0.93@D65*), yet speckle-free and full viewing-angled reflection with high resolution, well contrasted and colour neutral performance we really feel the v7 is closer than ever to obtaining that objective. When adding high acoustical transparency to that equation, the now patented technology utilised in the DreamScreen UltraWeave v7 is really a potential groundbreaking discovery that may very well be able to alter how we regard AT screens in terms of image quality even directly compared to regularly non-AT screens which has really been the Achilles´ heel of most AT screens thus far.

Using an AT screen in your cinema provides a number of advantages. First; the placement of speakers behind the fabric increases overall authenticity as the sound is actually emitting from where the action takes place. Also, an AT-screen provides a far cleaner surface, increasing the focus on the projected movie rather than the speaker-system. If you install the speakers in a (recommended) baffled setup, you will also increase the sound-level by several dB´s (which is a whole lot as the Decibel-scale is logarithmic). As the size of the screen increases, the acoustical disadvantage of placing a huge, reflective surface in the front increases as well. By other words; the larger TV or regular non-AT projection-screen you plan to install, the more trouble you´re likely to get in regards to controlling the sound-waves bouncing back and forth in your room. Last, but not least, an AT screen allows you to utilize the entire width of your room, maximizing the screen-size to its fullest extent!

The DreamScreen UltraWeave v7 has a matte white surface, bouncing off light from the fabric in an uniform manner. This means that the fabric is reflecting light in a full 160 degree angle, allowing the audience to be seated anywhere in the room without experiencing off-axis light-reduction which is the case for most positive-gain -and filtered screens. Also, this type of screen-material is notmaintaining the polarization of incoming light, which - if maintained - may cause visible artifacts when using active 3D-glasses.

Optimally, a dark "batcave" will provide you with the best image-quality from the UltraWeave v7, although immediate reflections surrounding the screen, both in ceiling, walls and floors are the most important to make certain is dark (preferably black) and as non-reflective in nature as possible.

*Please find benchmark tests using the Stewart Studiotek 100 non-AT matte white screen as the reference vs. a regular AT weaved screen. THE v7 HAS NOW BEEN MEASURED IN AT 0.93 GAIN (ABOUT 16% IMPROVEMENT FROM THE v6).

Our development-process has been long, challenging, yet in the end quite successful - in short;

2005 - v1: Dual layer vinyl weave (white) + knitted (grey). Bonded. Single reflecting layer.

2007 - v2: Dual layer knitted fabric, grey + white. Bonded. Single reflecting layer.

2009 - v3: Single layer knitted fabric grey only. Single reflecting layer.

2011 - v4: Single to three-layered separate layers fabric / synthetic weave. Tensioned, not glued. Single reflecting front layer.

2014 - v5: Three layered weave + knit. Bonded. Multiple reflected layers. PATENTED.

2016 - v6: Three layered weave + knit. Bonded. Multiple reflected layers. 30% finer front texture and 25% larger size compared to V5. Gain 0.80. PATENTED.

2020 - v7: Four layered weave + knit. Bonded. Multiple reflected layers. Gain 0.93, from 0.80 on v6. PATENTED.

The science

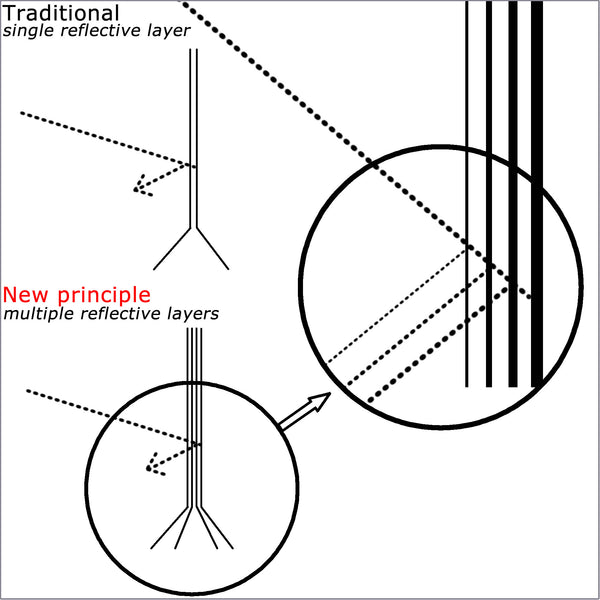

Our seventh generation AT fabric is a result of the research and development gathered in v1 through v7, where for our three latest generations we found that utilising several layers that actually reflects in combination rather than one front layer reflecting the image alone would potentially increase both image quality and sound transparency.

Figure depicts how the principle of regular single reflective layer vs. the multiple reflective layers works (International Patent # WO2014175747).

Figure depicts how the principle of regular single reflective layer vs. the multiple reflective layers works (International Patent # WO2014175747).

Utilizing several reflective layers, we have been able to combine a very fine, weaved front surface with three additional knitted layers, two white mid-layers, as well as a black backing layer.

The thin, weaved front-layer would not have worked alone, simply because the reflection of light would be too low. However, in combination with two backing-layers that assists on the reflection, the total amount of light-reflection is higher than ever before.

The "magic" that makes this technique unique is the fact that upon reflection, our eye only sees the structure from the front-fabric, even from right in front of the screen, although the layer behind is reflecting light as well. The front-layer works as a filter of kinds, providing the highest density, resolution and sharpness possible.

The second and third layer is also an essential part of the buildup. As the first layer provides the structural sharpness required for the image to be as seamless as it is, the second and third layer mainly needs to assist on light-reflection. As such, we are able to use a far rougher type of fabric that is knitted instead of weaved. A knitted fabric, often used in speaker-grilles, allows far more sound to pass through. However, as we found in our 3. generation fabric using only knitted fabric; the density and thus resolution and sharpness is not sufficient. In combination with the front, weaved layer, however, the knitted fabric has found it´s rightful place in the grid; allowing sound to pass through very effeciently while reflecting (loads of) light!

The black backing layer increased perceived contrast and is also utilizing the knitted type of fabric so that sound will pass more effeciently.

The result is a sharp, dynamic, high-resolution image free from common artifacts such as moiré and visible structure even from very short seating distances (2m or less). We have tested both LCD, DLP, SXRD and D-ILA, currently in resolutions up to 8K (e-shift) from a number of distances, and there is simply no way the extremely fine-weaved surface will be able to create interference with the projected grid, thus create moiré. As it is the front-surface that provides the visible reflective surface to the viewer, even as resolutions increase to 8K or beyond, you can rest assured that the V7 UltraWeave fabric will keep providing a moiré-free reflection.

Bonded, not tensioned layers

Although we have bonded the layers in both our 1. and 2. revision, we did not on our 3. and 4. version as we simply did not manage to get the results we wanted on the primary production-runs. Bonding the layers is a complex process that we finally have mastered in our 5. generation of fabric. Imperfect tensioning, resulting in space between a front, single-reflecting layer and its black backing layer is quite damaging to both image-contrast and sharpness, especially on sharp contrasted-objects such as a starlit sky. Using several reflective layers made it even more crucial to keep the layers perfectly tensioned. On the v7 UltraWeave-fabric, there is no space between any of the layers which in turn creates a sharper and more contrasted reflection than is the case when trying to manually tension the layers of fabrics.

The integrated black backing, in addition to increasing perceived contrast, absorbs excessive light which in case might have reduced sharpness and given "halo" artifacts if light is reflected on a wall behind the screen and back.

Super flexible = quick & perfect installation

Installing a regularly weaved AT fabric can be a real challenge. When you are to tension up a separate black backing layer as well, often made up of the same stiff PVC-weave, it is very hard to avoid distance between the layers. As the v7 is made up of super-flexible, pre-attached layers, it´s really easier than ever to tension the fabric perfectly onto even heavily curved frames using the available flexible grip rails.

You can even glue the available grip rails to any wooden or existing aluminum frame if you do not purchase one of our frames but rather recycle your current one. If you do want a new frame, however, our DreamScreen-frames includes fitted tracks, thus no need for glue.

Speckle free, full viewing-angle, high brightness reflection

One of the main issues with a number of projection-screens - especially those using a positive gain-factor, but also a number of ordinary gain fabrics - is the speckle phenomena. This is a quality-reducing incident that we have made huge efforts on avoiding. Speckled surfaces project a reduced resolution in brighter areas, as well as clear structural noise. Positive gain also reduces the stability of the viewing-angle, which is not the case for the UltraWeave v7 utilising a matte, fully 160-degree constant-gain reflective surface.

For our 7th generation DreamScreen UltraWeave we can proudly state speckle is no longer an issue, although the gain-factor is at an impressive 0.93.

Example of a (heavily) speckled (left) vs. a non-speckled (right) reflection

Example of a (heavily) speckled (left) vs. a non-speckled (right) reflection

Color neutrality and D65 compability

As every projector, although some being quite close to D65 from factory, outputs a less than optimal color gamut and greyscale, you always need to calibrate your projector to fit the specific screen material that is used. There are no actual standards on how a projection-surface should look like in terms of reflection other than the fact that it should reflect as much D65-calibrated light as possible throughout the entire greyscale. As such, the screen needs to reflect as close to 6500K as possible and also make certain there are no color-shifts in red, green or blue that would require the calibrator to compensate by reducing the output of the other color-channels to balance the RGB-output.

The DreamScreen UltraWeave v7 has been carefully tuned to make certain as much light as possible is maintained from the projector when calibrated to D65. Although providing charts that demonstrate that the v7-fabric is able to reflect D65 might not be very relevant as ISF and THX-certified calibrators have already calibrated hundreds of projectors to D65 using this fabric during the span of the UltraWeavee v5-v7-series, we have performed comparative tests in terms of light output available post-calibration from a given set of screen materials.

As initial measures indicated, the DreamScreen UltraWeave v7 measures about 0.93 gain compared to the regular non-perforated Stewart Studiotek 100, which is listed at 1.0 gain. Some loss of light-reflection is to be expected on an acoustical transparent screen that is matte white to begin with, and a level of 0.93 is very impressive in such regards.

TECHNICAL MEASUREMENTS / PROOF OF CONCEPT

ACOUSTIC TRANSPARENCY V7

Methodology is further elaborated below, but in short we have build a custom cabinet in highly rigourous MDF, insulated with absorption-material and a constant placement for the measurement-microphone. We use REW to analyse the A/B-measures with and without the fabric.

Measurements include all three layers of the v7-fabric (including the integrated black backing). 1/12-smoothing. Measurements indicate high acoustic performance with a max drop of 3,9dB@20kHz and an average drop of just below 3,3dB.

MEASUREMENT METHOD AUDIO TRANSPARENCY

Our measurement-cabinet is fully isolated using a studio monitor to output the test-sweep to a calibrated miniDSP UMIK-1 microphone using REW-software on our mac to analyse the measurements. The microphone as well as the studio-monitor remains at the exact same location during measurements of each fabric to ensure repeatability. Several separate sweeps are made to make certain each measurement is fully repeatable. The various speaker fabrics are tensioned to an interchangeable frame and placed about 15cm in front of the monitor and about 40cm from the microphone. However, even a slightest movement of the microphone may alter the results, and the cabinet also introduces cancelleations and boosts due to its inherent dimensions.

GAIN FACTOR - OFFICIALLY 0.93

In general, many producers of AT fabrics seem to inflate their listed gain-levels. Stewart, however, has been a studio-reference for many years, and thus we assume their gain-levels are correctly listed, and as such we are using their Studiotek 100 as our reference. There are some indications the on-axis gain of the Studiotek 100 is actually a little higher that 1.0 gain, one report indicated 1.02 (https://www.accucalav.com/accucal_fr...screen_report/).

When a matte white AT screen is listed to obtain a gain-level of 1.1 there is simply a logical breach somewhere. When adding holes for the sound to pass through a fabric, the consequence has to be that light-reflection is reduced accordingly unless the fabric has a more positive gain-factor than 1.0 to begin with. Gain-factors higher than 1.0 introduces artefacts such as speckle and / or hot-spotting, specially visible in bright / white areas of the image.

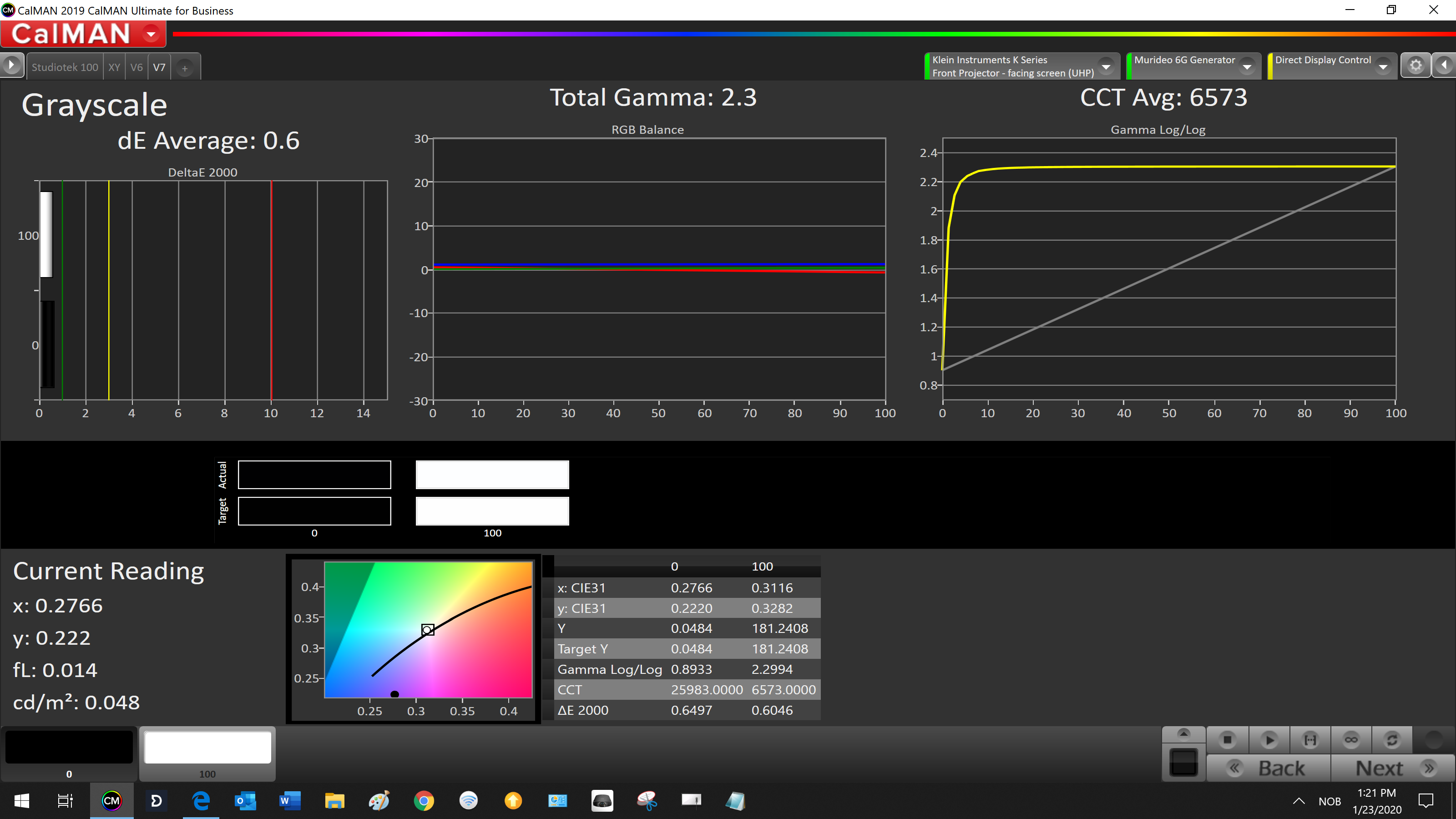

The calibrator that did these measurements is Gorm Sorensen, a Norwegian THX and ISF-certified calibrator, performing hundreds of calibrations every year. Calibrations are made in a «simulator», which is in essence is a batcave, covered in black fabric all over to make certain reflections will not reduce measurement-accuracy.

The measurement meter is a Klein K-10A referenced by a Photo Research PR670 spectroradiometer. Calman pro software.

Gorm Sorensen, an ISF and THX-certified professional calibrator, is performing the measurements

First, the projector is D65-calibrated on our reference fabric, the Stewart Studiotek 100

The regularly weaved AT screen fabric and then the DreamScreen UltraWeave v6 and then v7 is henceforth attached directly on top of the non-AT Stewart fabric to make certain there is as little distance-variations as possible.

Reference measurement - the Studiotek 100

First, we calibrated a video projector to the Stewart Studiotek 100 @D65 (matte white, gain 1.0, non AT). No further calibration was done for the comparison of the other fabrics. The dE averaged at 0,23 on the Studiotek. The Studiotek topped at 203,9 candela / m2 at 100 IRE.

Test fabric #1: woven 1.1 gain mfg rated fabric

Then, we placed the 1-layered woven AT material rated at 1.1 gain directly on top of the Studiotek without any movement of the meter. We added a black backing to make sure the gain is measured correctly. The fabric reflected D65 with a dE of 1,89 (not recalibrated) for this particular fabric and reflected a maximum of 167,8 cd/m2 at 100% IRE.

The producer indicates a gain of 1.1, while our measurements clearly indicate that our assumption of inflated values are correct. Their measured reflection is about 82,2% of what the Studiotek 100 reflects, by other words a gain-factor of about 0.82. Some light-reflection may be gained after a D65-calibration, but certainly not as much as 25%. Our estimated gain-factor of this fabric is 0.86, leaving about 5% margin that compensates for the fact that the Studiotek might inherit a gain value of some 2% over unity (1.02), as well as a general measurement buffer.

Please note that this specific 1-layered woven screen uses a very tightly woven pattern to obtain its gain reflection values. We have measured one layer of this fabric with a peak (20kHz) dB drop of more than 5dB, and adding a black backing it would add at another 1-2dB loss.

Test fabric #2: UltraWeave v6 0.8 gain mgf rated fabric

Then, we measured the DreamScreen UltraWeave v6. With an average dE of 1,16, the v6 measures 157,9 cd/m2 at 100% IRE, about 77,4% of the 1.0 gain of the Studiotek and thus a gain-level of about 0.81 (rated at 0.80) leaving about 5% margin.

Test fabric #3: UltraWeave v7 0.93 gain mfg rated fabric

Last, we measured the DreamScreen UltraWeave V7. With an average dE after calibration of 0,6, the v7 measures 181,2 cd/m2 at 100% IRE, about 88,9% of the 1.0 gain of the Studiotek and thus a gain-level of about 0.93 leaving about 5% margin.

Conclusion

The gain-level of the DreamScreen v7 is at a comparable level of about 0.93 while the 1-layered woven fabric we compared with, which is rated by the manufacturer to provide 1.1 gain, has as comparative gain of 0.86. The UltraWeave v6 is reconfirmed at 0.80.

Calibration data results Stewart Studiotek 100 calibrated at 6500K (reference)

Calibration data results of the regularly weaved fabric calibrated at 6500K (test fabric #1)

Calibration data results DreamScreen UltraWeave v6 calibrated at 6500K (test fabric #2)

Calibration data results DreamScreen UltraWeave v7 calibrated at 6500K (test fabric #3)

Calibration data results DreamScreen UltraWeave v7 calibrated at 6500K (test fabric #3)

Omtaler

Det er ingen omtaler ennå.